Metal Spray Powders / Equipment

Easy to use and cost effective method to protect and repair valuable components against wear and tear.

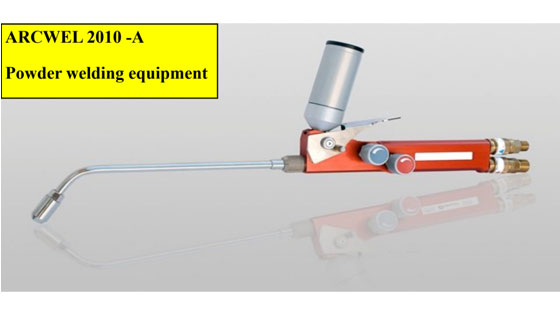

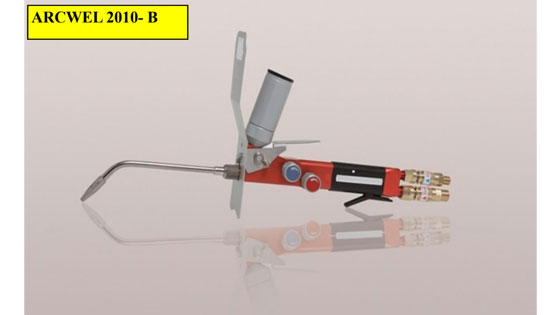

Metal powders are applied with a special oxy acetylene torch (ARCWEL 2010-A or ARCWEL 2010- B) and fused simultaneously to the surface of the metal part.

Precise and thin overlays can be made by diffusion ensuring a perfect bond below the melting point of the base metal.

Coatings made by this process have only a minimum of dilution and therefore retain the original properties.

Typical Applications are repair and overlay of glass, press or plastic injection moulds, repair of manifolds, casting defects, tinning of stabilizers when cementing tungsten carbide inserts.

Extending lifetime of feeding screws, Mixer blades, Debarker Tools,etc.

A variety of Nickel Base Spray powders are available ranging in Hardness from HRC 13 to HRC 64 .

Get A Quote View Pdf| ARCWEL

CODE |

DESCRIPTIONS & APPLICATION | TECHNICAL

DETAILS |

| 2015 | Nickel base powder for joining and overlaying of parts where machinability good bonding is of prime importance Used as a bonding layer and filler powder when applying tungsten carbide (TCI ) inserts or composite rods to sta bilizers etc. Fusion temperature (°C) 1040 –1080 | Hardness : 13-18

HRC Composition of Pow der. Ni, Cu, Si, B, |

| 2020 | Nickel base powder for joining and overlaying of parts where machinability is of prime importance. For use on glass, press or plastic injection moulds, manifolds, casting defects, tinning of stabilizers when cementing tungsten carbide inserts . | Melting range:~1050- 1260 º

Hardness: 200-240 HV 30 Service temp.: max: 600ºC |

| 2030 | Nickel based flame spray powder (spray and fuse) with Boron and Silicon additions for overlaying of cast-iron, steel, eg. 4140/45 stainless steel and nickel alloys, Low melting point, good fluidity, easy to machine , Excel lent resistance against corrosion, friction and heat. | Melting range:~1050- 1150 º

Hardness: HRC 30- 35 Service temp.: max: 600ºC |

| 2040 | Nickel Chrome alloy powder for anti wear coatings against metal to metal pressure, For use on ,glass and plastic moulds, press tools &

Thick coatings or build ups are possible. |

Melting range:~1050- 1260 º

Hardness: 360- 420HV 30 Service temp.: max: 600ºC |

| 2060 | Nickel Chrome alloy powder for anti wear coatings against abrasion and erosion. use on conveyors screws, guide rollers, cams, Valve steam Seats , Flow control Valve parts Mixer blades, fan blades, pump plungers etc. | Melting range:~1050- 1260 º

Hardness: 56-62 HRC Service temp.: max: 600ºC |

| 2070 –40

2070-50 2070-60 |

Tungsten carbide alloy powder (40, 50 , 60 % WC) for coat ings with maximum resistance to abrasion and erosion. For knives, feeding screws, Mixer blades, Debarker tools, stabilizers, | Melting range:~1050- 1260 º

Hardnes: 57-64 HRC Service temp.: max: 600ºC |

Above powders are available in the following Particle size Range 1 ) Powder welding ( PW) µm 106/20

2) Flame spraying spray-fuse ( SF ) size µm 106/45 or 106/36

3) HVOF Spraying ( HVOF ) µm 53/20

4) PTA welding ( PTA) size µm 150/53