Oil & Gas App

Oil & Gas App

Products for Down Hole Tools Repair and Protection Stabilizers are an important Part in Down-Hole Applications and are typically made from

4145 or 4145 H Alloy steel .

The blades are subject to severe abrasion, pressure and impact causing heavy wear.

Depending on the application and equipment available we offer a variety of products

to rebuild and protect stabilizers, compressor rods , pump shafts, pump sleeves etc.

We have over 50 years experience and can offer you proven products and expert advice.

Additional Details

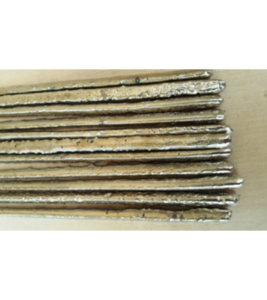

ARCWEL -788 –G Rope

Self fluxing flexible type tungsten-nickel alloy brazing wire.

For maximum protection on conveyor screws, drill bits, stabilizers etc.

2015 SF METALSPRAY POWDER

- Used as a bonding layer and filler powder

when applying tungsten carbide (TCI ) inserts

or composite rods to stabilizers etc. - 2070 SF Nickel Tungsten Powder for protec-

tion of edges and stabilizers and drilling tools.

ARCWEL 790 G COMPOSITE RODS (HF1000)

Made from Crushed tungsten carbide held in a nickel bronze matrix. For use on fishing tools ,downhole reamers, openers, coring tools, mill- ing tools

ARCWEL 2010 -B

Special Oxy-Acetylene Torch for Preheating, Spraying

and Fusing of Metal powder

- Heat shield for extra protection

Integrated quick action shut of valve . - Gas mixture which was previously adjusted is

maintained , saving time when spray operation has

to be interrupted frequently - Highest level of operational safety

- Accessories as per Model 2010-A

| 2015 | Nickel base powder for joining and overlaying of parts where machinability good bonding is of prime importance Used as a bonding layer and filler powder when applying tungsten carbide (TCI ) inserts or composite rods to sta bilizers etc. Fusion temperature (°C) 1040 –1080 | Hardness : 13-18 HRC Composition of Pow der. Ni, Cu, Si, B, |

| 2070 –40 2070-50 2070-60 | Tungsten carbide alloy powder (40, 50 , 60 % WC) for coat ings with maximum resistance to abrasion and erosion. For knives, feeding screws, Mixer blades, Debarker tools, stabilizers, | Melting range:~1050- 1260 º Hardnes: 57-64 HRC Service temp.: max: 600ºC |