Marine & Repair Shops

Marine Repair Workshops / Maintenance & Repair Solutions

Problem Wear on Propeller shati

( Material Carbon Steel)

REPAIR SOLUTION (SMAW )

GOLD 330-E Cr Ni Alloy

Additional Details

Wear or Bearing surfaces : Material Cast iron, Rebuild worn or damage surface

Solution: 410/420 – SMAW or 420/728 GTAW

Wear or damage on Propeller : Al Bronze, Weld Repair Solution:

GOLD 907 – SMAW or 628 -GTAW

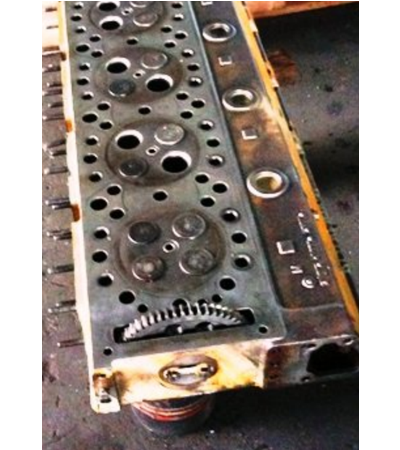

Cylinder heads and Engine blocks repair products

GOLD 410/420 for weld repairs on cracked or worn cylinder heads (cast iron) engine blocks and pump housings. ARCWEL 2020 SF Thermal spray powder

Problem : Wear on Piston Crowns

Solution : GOLD 320/330 SMAW

for rebuilding

Marine Repair Workshops / Maintenance & Repair Solutions

Filler Materials for rebuilding and hard facing of Valves, Valve Spindles &Valve

Valve seats rebuilt by GTAW Process, Filler rod GOLD 1045 T (Co 6) Alloy

Valve coated using PTA Process

Filler: Metal powder Nickel Cobalt

“ARCWEL 2006 PTA”

Valves and Valve seats of Diesel engines are subject to wear by high temperature and metal to metal friction.

Depending on Welding equipment available the following Filler metals have proven successful for repair and protection.

- SMAW : GOLD 330 as build up and GOLD 1045 (Co6) as top layer

- GTAW: GOLD 510-T (625) –GTAW as build up and 1045 –T (CO 6 ) as final Top layer

- PTA : ARCWEL 2006 PTA -Powder

Above filler metals can increase the lifetime of Valves many times