Brick & Clay ,Ceramics Production

BRICK &CLAY ,CERAMICS PRODUCTION ,WEAR PROTECTION

Maintenance& Repair Solutions by Welding

Ball Mill Shell :

Due to high stress cracking of shell can occur.

Base Material : low alloy steel Weld repair: SMAW

Filler electrode recommended

GOLD 330 or alternative

GOLD 627

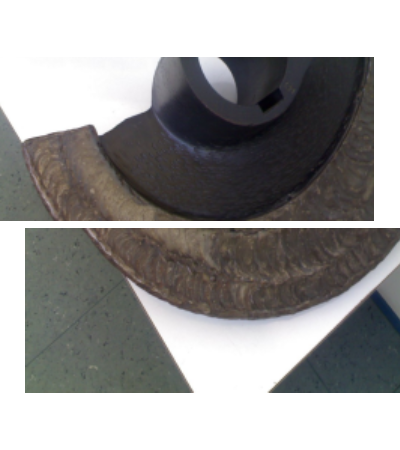

Wear on Molds used for ceramic tile production :

Hardface and Repair of Molds using

GMAW – PROCESS

Filler Wire : 600 –SG (HRC 55-60)

Additional Details

MAINTENANCE WELDING IN CERAMICS ,BRICK & CLAY PRODUCTION

Quartz in mixture causes severe abrasion MIXER BLADES on mixer blades , screws and moulds

FEEDING SCREW

Wear on shaŌ and flight area Base metal: Structural /Cast Steel. Welding process: SMAW

Use GOLD 320 for rebuilding and thereaŌer apply one or two layer of

GOLD 750 or 760 for long life time.

Wear on Clay or Sand Mixer blades

NICKEL TUNGSTEN CARBIDE WIRE 788-G

AUGER- SEGMENT

For repair & protection use

Oxy fuel welding process and filler rods 788 G – or Thermal spray powder Code 2060 –SF or 2070 SF