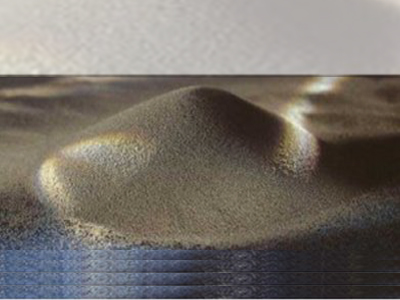

WEAR PROTECTION WITH THERMAL SPRAY POWDERS

Wear protection with Thermal Metal spray Powders is versatile method of depositing high quality deposits on relatively low cost surfaces. Medium and high hardness materials, and carbide composites can be deposited on a variety of metals to achieve diverse properties such as mechanical strength, wear and corrosion resistance. More then 150 different metal powders are available to suit most applications

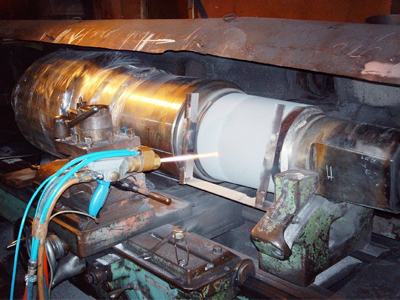

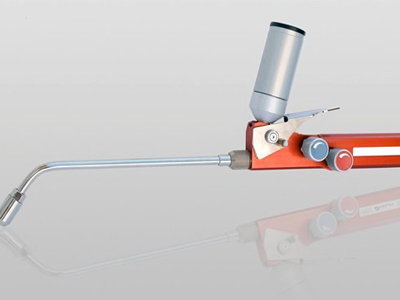

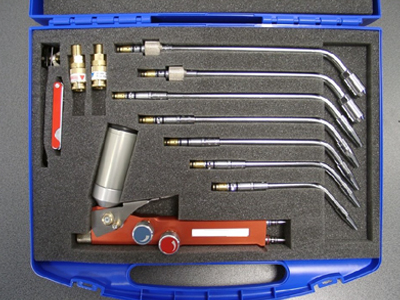

We supply Metal Powders for use with the following Processes:

- Cold spraying (CS)

- Detonation flame spraying

- Oxy-acetylene powder welding , Spray & fuse (S&F)

- Plasma spray (APS ) & Plasma transferred arc surfacing (PTA)

- High velocity oxy-fuel spraying (HVOF-HVAF )