Mining, Quarries/ Earthmoving

Mining, Quarries/ Earthmoving

Excavator Buckets,

Grader Blades,

Dragline Buckets, Dozerblades,

Crusher Hammers,

Truck Rollers and Pads etc,

The Above Parts are subject to wear by abrasion, impact, friction or corrosion causing wear and decrease in efficiency and lifetime of valuable Equipment.

We have over 50 years experience in wear protecon and can advise you on the best method, process and the right filler (welding) material.

We supply wear resistant GMAW Wires, SMAW Electrodes , GTAW (TIG ) rods & Tungsten Carbide Brazing Wires.

Contact us for your best solution .

Additional Details

Part: Buckets

Base material: Un/low alloy steel

Problem:

Wear on bucket and bucket teeth due to abrasion

,friction and impact by coal, sand, stone etc.

Equipment looses efficiency, causing increase in

operating costs.

Solution:

Protect bucket lips, sides and other wear areas by

applying a wear resistant high alloy Chromium

Carbide material.

Welding process: SMAW (Stick electrodes)

Welding material: A) GOLD 750 (HB63)

B) GOLD 760

JAW CRUSHERS –CRUSHER JAW PLATE

Used to crush (reduce) hard materials such as coal, stone etc.

Crushers are normally made form a wear resistant Manganese steel.

Problem:

The high impact and compression causes the Jaw

plates to wear out and the crusher looses crushing efficiency.

Solution:

Weld repair

Welding process: SMAW (stick electrodes)

Welding material:

GOLD 740

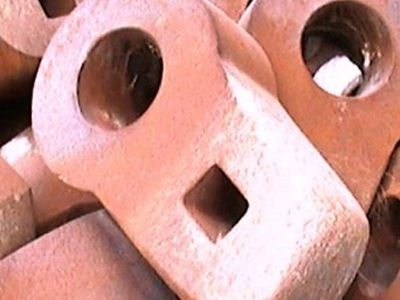

HAMMER MILL CRUSHER (COAL PACTORS )

widely used crusher system Made from austenitic manganese steel or low alloy cast steel

Problem:

The Hammers crushing the raw materials

are subject to extreme impact/pressure

and abrasion and tend to suffer wear and

tear

Solution:

Rebuild worn hammers by using one

of the following Welding materials.

Gold 740 for restoring dimension

and thereafter apply 2 layers of GOLD

750 OR GOLD 76O for maximum protection

Wear on Crusher Housing (Bearing)

Repair welding : GOLD 740 or GOLD 710

Machinable weld deposit

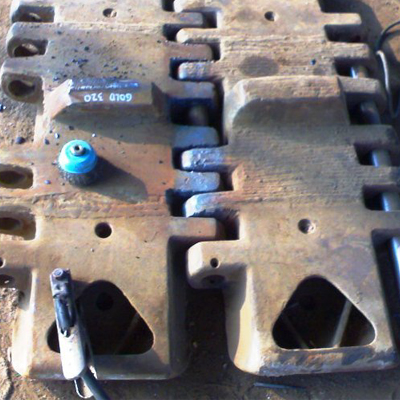

Machine: EXCAVATOR

Part: Track pads

Base material: Low alloy cast steel

Problem:

Wear on truck pads due to friction and pressure.

Equipment looses efficiency, causing increase in operating costs.

USE GOLD 710 or GOLD 740 FOR REPAIR

Wear protection of coal mining buckets with

GOLD 750

Coal cutter Bit hardfacing

GOLD 750/760

Coal mining machine protection

GOLD 750/760